- Home > News

News

With the increasing demand for environmental protection, green solvent-free polyurethane composite adhesives have developed rapidly in the flexible packaging industry. The use of non - woven compound flexible packaging products, structure and other methods of processing flexible packaging products consistent. The structure of composite flexible packaging products typical: the first substrate / oil / printing / second composite adhesive material, printing ink and adhesive is directly connected with the printing ink, resin, solvents, pigments, additives and printing quality of the non solvent composite flexible packaging product quality has great influence on the appearance, such as peeling strength etc..

ONE. flexible package composite structure

A typical two - layer plastic / plastic composite: printing inks are in direct contact with solventless adhesives.

Two, flexible packaging ink

At present, China's soft packaging plastic used in India ink, gravure printing ink based.

Three, the impact of printing ink on solvent-free composite quality

Printing ink in direct contact with the non solvent composite adhesive, printing ink with resin, solvents, pigments and additives and the printing quality are on the quality of non solvent composite flexible packaging products such as appearance, has a great influence on the peel strength. These effects are more pronounced when compared with solvent based composite adhesives for flexible packaging products (dry composite).

1, the appearance of the impact

(1) the influence of the fineness of the ink on the appearance of solvent-free composite appearance

The fineness of the ink has a great influence on the appearance of solvent-free composite. Solvent free composite adhesive glue is low, there is no solvent characteristics and advantages of the composite, but also means that the low glue thinner layer, if the ink fineness is not enough, there is deep in the uneven ink layer, solvent free adhesive cannot fill these rugged, will not cause local glue, causing white spot / bubble.

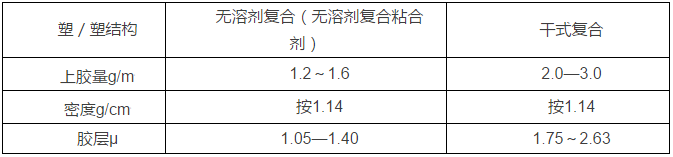

The following table is a non solvent composite and composite dry glue for comparison, plastic / plastic structure, non solvent composite glue 1.2 - 1.4 g/m2, only 1.05 to 1.40 microns thickness, dry compound glue layer is larger, thicker.

Table 1 Comparison of solvent free composite and dry composite

(2) residual solvents and solvents on the fineness of ink effects of non solvent composite appearance is mainly from two aspects of factors, is a pigment fineness, grinding degree is two, if the ink fineness is not enough, there is deep uneven micro, in serious cases, solvent free adhesive cannot fill these rugged. It will cause the appearance of a problem, namely white / bubble.

The residual ink, solvents, and solvents of the printing ink all affect the appearance of the solvent free composite. Printing ink solvent residue is more direct, coiling, the composite without solvent and then curing, the residual solvent volatilization of lead to no chance, soft packaging products of composite mist, even produce soluble ink; printing ink and dry compound, even if there are more residual solvents, the oven will evaporate, reducing the influence of the final product will.

In addition, the solvent type of printing ink also has no influence on the solvent free composite. At present, due to environmental pressures, benzene soluble ink without increasing the amount of alcohol, alcohol solvent containing active hydrogen, easy to group A and solvent free adhesive points (NCO group), if the alcohol solvent residue, will consume A components, effect of drying, adhesive and adhesive in no cure, reacts with alcohol solvent in the ink layer, easy to cause the phenomenon of ink solution.

The solvent residue in printing ink is closely related to ink, resin, solvent system and drying degree.

(3) influence on Performance

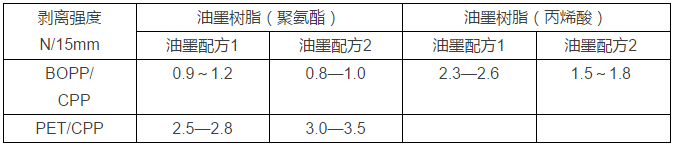

Printing ink has great influence on the performance of solvent-free composite products. The effect of ink resin and ink formulation on peeling strength is studied in this paper.

In the experiment using the same solvent free adhesive, BOPP, CPP films of the same resin polyurethane ink made 2 ink formulation, acrylic resin ink made 2 ink formulation, the peel strength comparison test by composite machining. Detailed results are shown in table 2.

Table 2 Effect of ink category on peel strength

Three. Conclusion

Can be seen from table 2, the different types of ink resin has great influence on the peel strength for BOPP/CPP structure, using polyurethane resin ink composite products peel strength is low, and the use of acrylic resin ink peeling strength; different ink formulations also have great influence on the peel strength.

1, ink, pigment fineness and degree of grinding affect the appearance of solvent-free composite, if the fineness is not enough, easy to cause white spots / bubbles, and thus affect performance.

2, the residual solvent in the printing ink layer has more effect on non solvent composite products, easy to cause the mist, soluble ink in the printing process; Shen, should try to reduce printing solvent residue, especially alcohol solvent residue.

3, different resin types of ink have a great influence on peel strength.