- Home > News

News

In gravure printing, the change of image level mainly depends on the thickness of ink layer. It can not be adjusted in the middle of printing as well as other printing methods, but depends on the size of mesh point and the rate of ink transfer.

The shape of the 1. net points and the transfer of the ink;

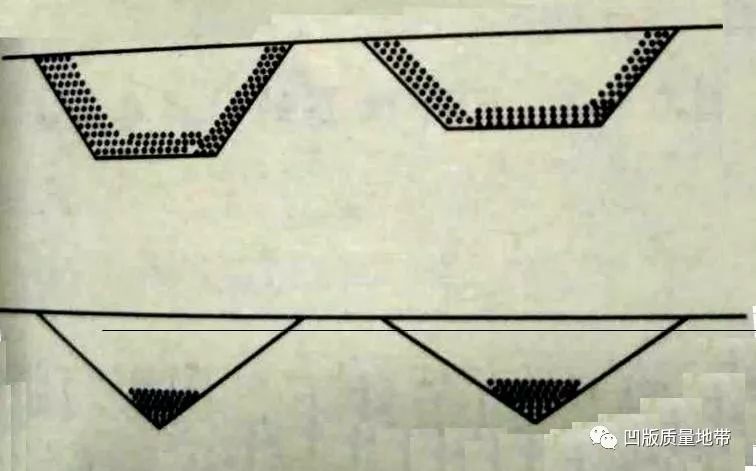

The shape of the acupoints of the gravure net is different from the plate making method, the net acupoint of the electronic engraving is inverted conical, and the corroded net acupoint is the basin shape. At the same depth, the volume of the cone is lower than that of the pelvic cavity. As shown in the picture.

However, there is no dead angle on the smooth surface of the engraving mesh, and the performance of the actual transfer of ink in the process of printing is better. The rate of corrosion pots of ink transfer is about 50%.

The effect of 2. plate wear on the amount of ink;

The printing process, due to the impact of friction force, make the plate surface wear, wear the inking opening smaller (i.e. net value smaller), shallow depth, resulting in unit area of the ink is small, the total amount of ink is also reduced. For the electric engraving and etching plate, wear the same degree of influence, glyphograph than the much larger version of corrosion. If the same amount of wear is worn, the decrease of the volume of the electric engraving is about twice less than that of the corroded plate.

3. the type and nature of the printed matter;

Under the same printing pressure and ink viscosity, high smoothness and softness of the substrate can increase the capillary force between the substrate and the printing plate, thus improving the transfer rate of gravure ink.

4. ink viscosity;

With the increase of the ink viscosity, the transfer rate of the ink has decreased. It is particularly evident in a small, deep deep mesh point.

5. printing speed and printing pressure;

When the printing pressure is increased, the transfer rate of ink will increase in a certain range, but the transfer rate beyond this range will decrease. As the speed of printing increases, the time of contact between the printing ink and the ink is short, so the transfer rate of the ink is reduced.

6. temperature;

As the temperature rises and the viscosity decreases, the transfer rate of ink is increased.