- Home > Products > Gravure ink

Gravure ink

Luz series intaglio ester soluble polyurethane integrated ink is developed with high-grade imported polyurethane resin, pigment and composition. It is a kind of ester soluble environmental protection intaglio ink without toluene and butanone. It meets the requirements of safety and health. It is suitable for low-speed to high-speed printing with different solvents. It has good printing adaptability and excellent cooking resistance.

【Product characteristics】

1. It is suitable for film printing of BOPP, CPP, pet, nylonetc;

2. Excellent printability, good ink transfer, suitable for 50 to 250 meters per minute printing;

3. Bright color, high color density, good leveling and dot reproducibility, suitable for multiple printing;

4. Greatly improved the printing site, no toluene, no butanone, reduce environmental pollution;

5. The solvent residue of printed matter is very low, especially suitable for packaging with high hygienic requirements;

6. It can be used with curing agent to achieve excellent boiling and cooking effect.

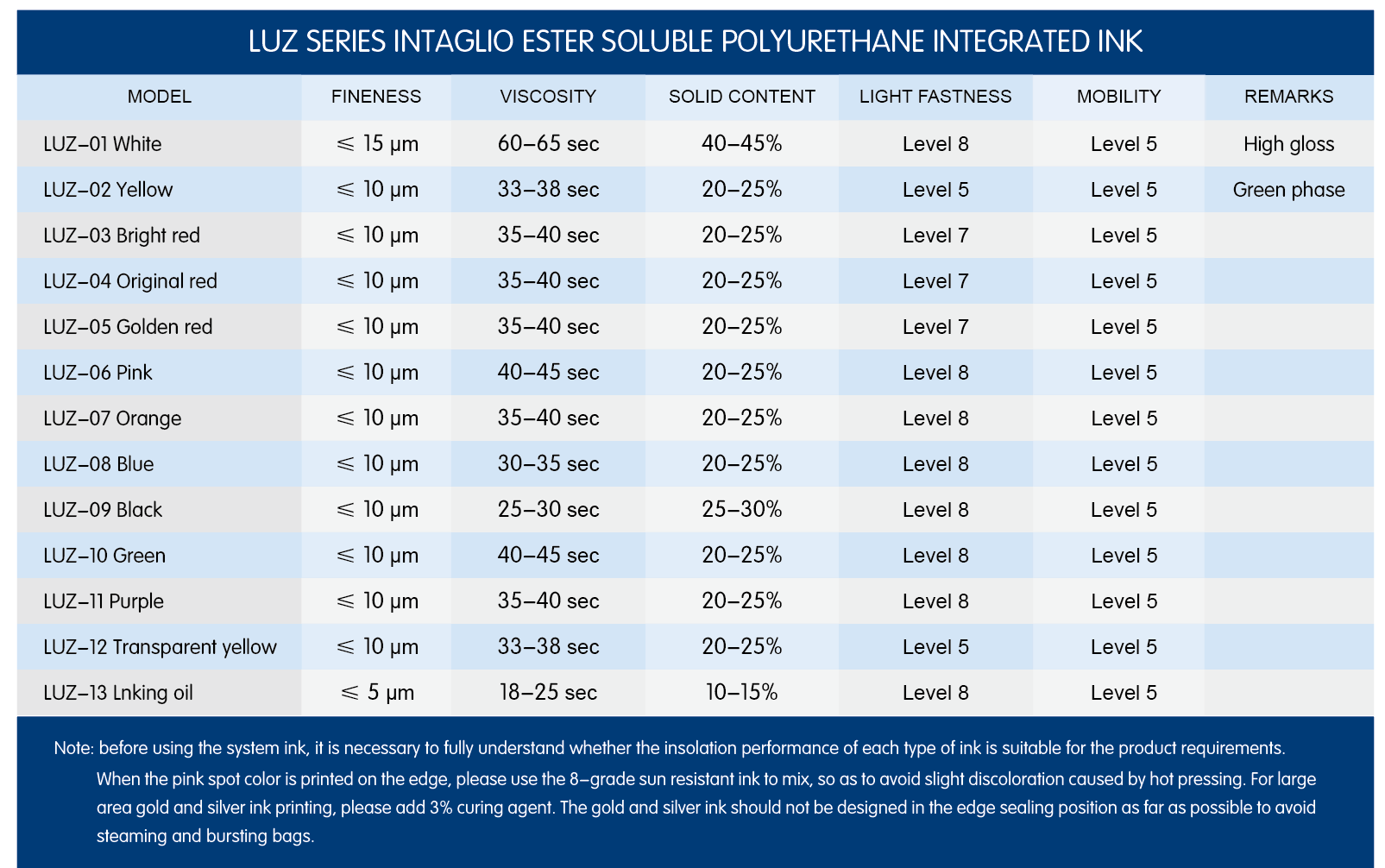

【Performance overview】

【Applicable substrates】

1. BOPP, CPP (above 38 dynes)

2. Pet, nylon (treatment degree above 52 dyne)

3. Printing grade Pt, K coating film

For other special purpose film substrate, please contact our technical department

【Usage and precautions】

1. before use, it should be fully stirred to make the ink in the barrel uniform and have good fluidity;

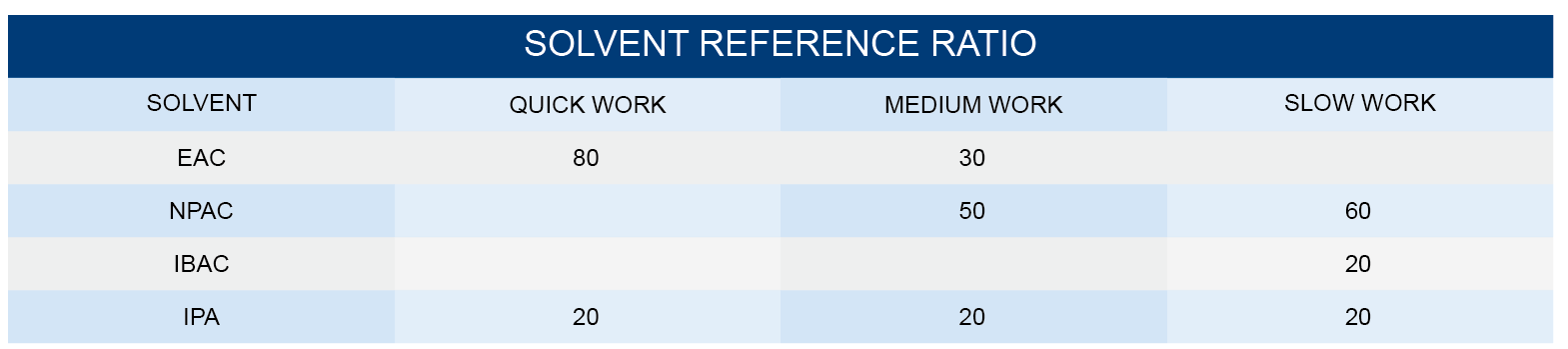

2. When diluting the ink, first prepare the diluting solvent, add it slowly under the condition of agitation, and avoid adding a large number of rapidly;

3. It can not be mixed with other different types of ink, so as to avoid resin separation and can not be used

4. When the ink is used in a wet environment or in a printing plate with less ink consumption, it is recommended to use a slow drying solvent, and please increase the oven temperature and air volume, so as to prevent the ink from bringing too much water into the air, resulting in tackification, blocking, color reduction, back sticking and other phenomena;

5. This product is inflammable and should be kept in low temperature to avoid exposure to the sun and rain.

6. The ink with * is boiled and boiled. It can be used in combination with curing agent for printing of boiled and boiled products. The amount of curing agent added is 3-4%. The product without * is only suitable for printing of light packaging products

【Quality guarantee period】

Please seal the ink tightly in the container and store it in the shade ventilation place. The temperature should not be higher than 40 ℃ to avoid light, so as not to affect the use of the product.

In view of the above conditions, it is recommended that the storage period of ordinary color ink shall not exceed one year; that of white ink shall not exceed six months; and that of gold and silver ink shall not exceed three months.

Disclaimer: the technical data of this data is determined under the condition of our company. However, as the actual use conditions and methods of products in users are beyond our control, we cannot guarantee or guarantee the technical data provided.

The company is not responsible for the possible losses. Please conduct sufficient and necessary tests before use.